What is the difference between GOB LED display and COB LED display?

In the packaging technology of LED display screens, GOB and COB are two new technologies, so what is the difference between these two technologies? Many people are familiar with GOB, while COB is the "star product" of LED display screens in the past one or two years. It is a new packaging technology that completely changes the LED manufacturing process. So what are the advantages and disadvantages of these two LED display screen technologies? Let the editor reveal these answers below.

In the packaging technology of LED display screens, GOB and COB are two new technologies, so what is the difference between these two technologies? Many people are familiar with GOB, while COB is the "star product" of LED display screens in the past one or two years. It is a new packaging technology that completely changes the LED manufacturing process. So what are the advantages and disadvantages of these two LED display screen technologies? Let the editor reveal these answers below.

Definition and Overview

Definition and Overview

1.What is GOB LED display and its features and advantages

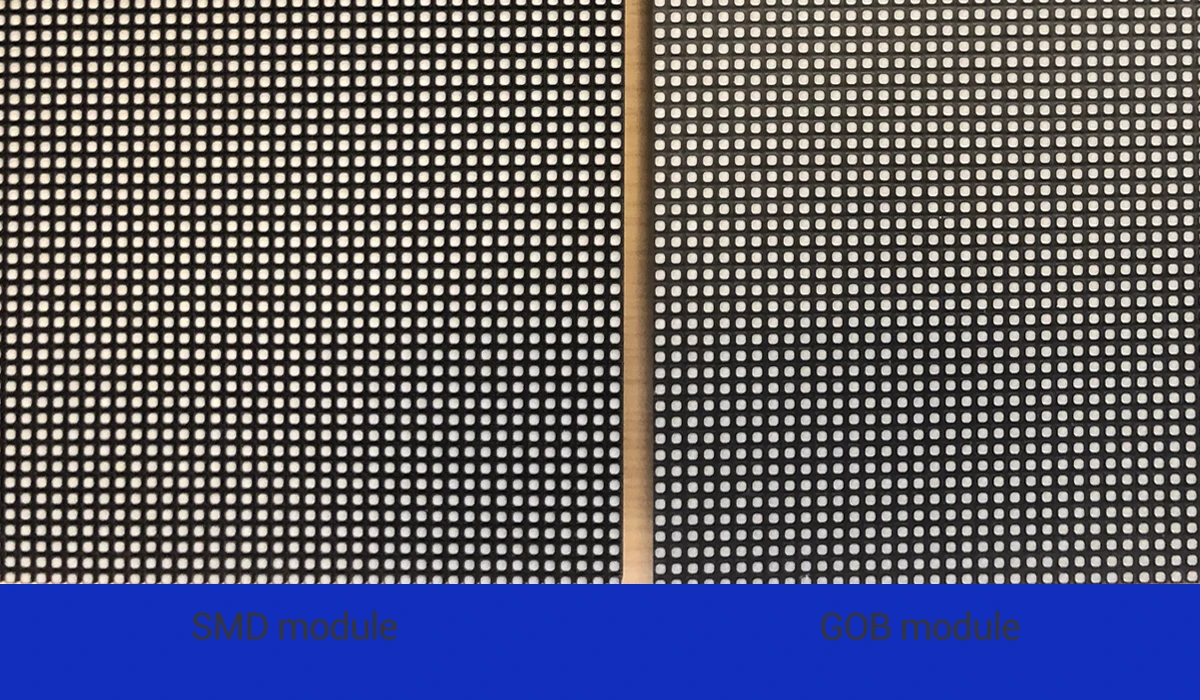

GOB technology is an improvement on SMD (surface mount packaging) technology. It increases the protection level of the display screen by adding a layer of transparent protective glue between the LED lamp beads and the PCB board. Its purpose is to increase the anti-collision and waterproof performance of the LED display screen.

Features and benefits

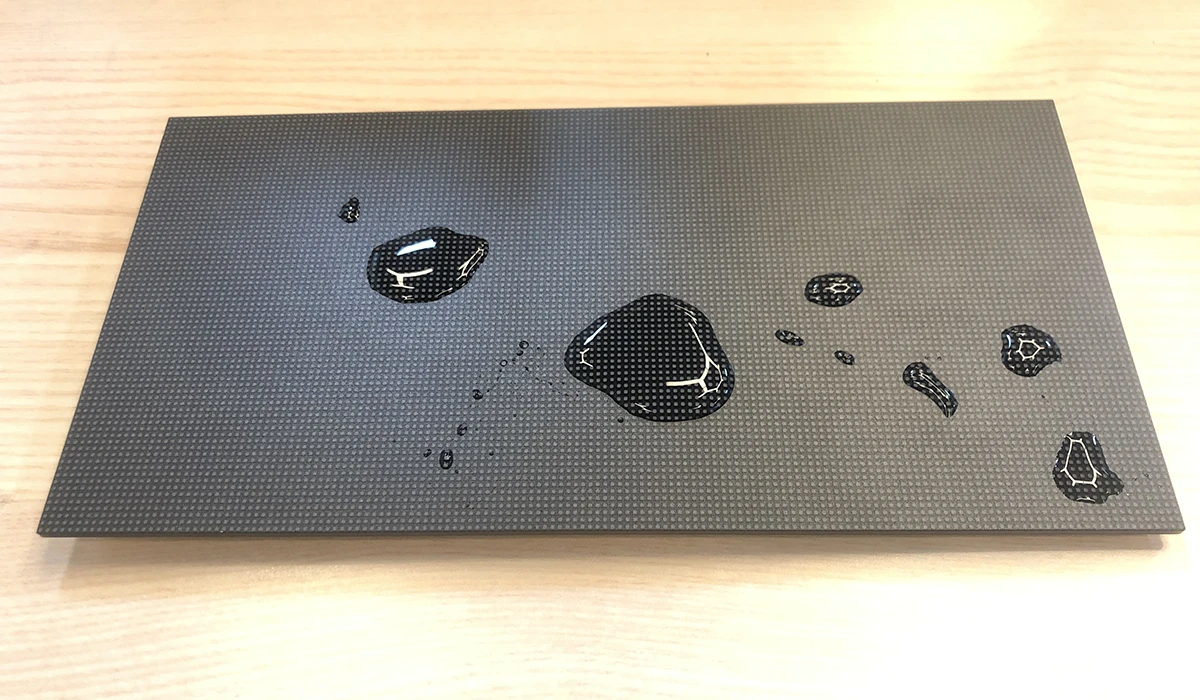

a. The GOB display screen uses a new type of optical thermal conductive nano-filling material. Through a special process, the PCB board and SMD lamp beads of the LED display screen are packaged together to form an effective protective layer. This design gives the GOB display screen an extremely high protection level, waterproof, moisture-proof, dust-proof, corrosion-proof, anti-blue light, anti-static, and can even reach the ultra-high waterproof level of IP68. This means that the GOB display can maintain stable performance even in extremely humid environments, without failures such as dead lights, making it very suitable for advertising screens outside shopping malls, construction site scheduling and other occasions.

b. Since GOB technology adds a solid protective layer to the surface of the display, when the display is hit or bumped, it can better protect the internal lamp beads and circuits and reduce the possibility of damage. This is especially important for displays used in uncontrollable handling and transportation environments, as well as crowded environments, because in these occasions, the display is more susceptible to physical impact. Even with a slight bump, the GOB display can maintain normal operation, greatly reducing the after-sales rate and extending the service life.

c. Since the GOB display uses special optical processing technology to achieve the conversion from point light source to surface light source, the light of the display is more uniform and soft. This design not only improves the display effect, but also greatly increases the viewing angle, allowing users to get clear and bright images even when watching from extreme angles. This is especially important for occasions where multiple people need to share display content, such as conference rooms, shopping mall advertisements, public places, etc.

d. Since GOB is an upgrade of SMD technology, the LED display product specifications it targets are still P1.5 and above products.

2.What is COB LED display and its features and advantages

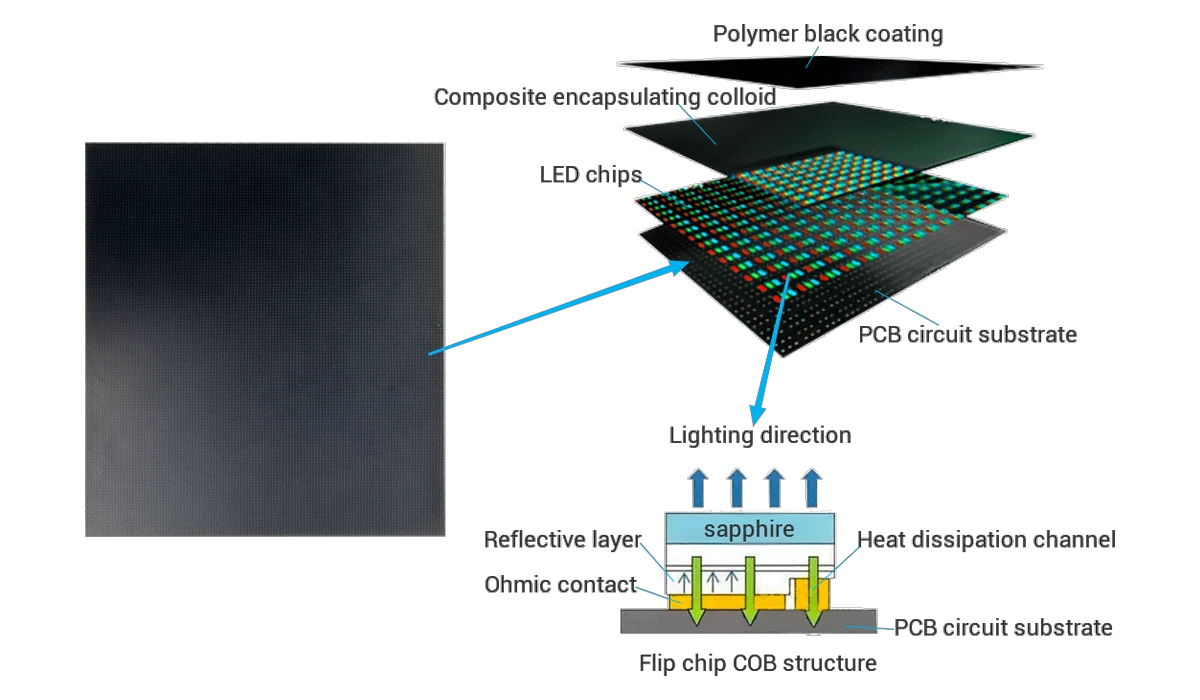

COB is a new packaging technology. Unlike traditional packaging, it no longer needs to be packaged into lamp beads and then welded. Instead, it directly packages the LED light-emitting chip on the PCB board, which simplifies the entire packaging process, reduces the use of accessories, and makes the entire packaging process simpler.

Features and benefits

a. Compared with traditional SMD surface mount packaging, COB technology can achieve a smaller dot pitch. This technological breakthrough enables the COB display to present more delicate and clear images, especially when viewed at close range, its high-resolution advantage is more obvious. It is generally suitable for display screens with specifications below P1.25. It is a new audio-visual feast that users with high-end display needs cannot miss.

b. The components of the COB display are all packaged in the PCB board. This design not only reduces the possibility of damage to the screen during transportation and installation, but also shows better impact resistance than traditional displays. Thanks to its "flat" luminous characteristics, it also effectively reduces the interference of moiré, thereby significantly improving the display quality.

c. Due to its unique packaging method, COB packaging technology greatly reduces the maintenance rate of the display. During the production process, the manufacturing process of COB display screens is relatively simplified, reducing manual operation links, thereby reducing the risk of failures caused by improper operation. At the same time, COB display screens have excellent heat dissipation capabilities, and heat can be directly dissipated through the PCB board, effectively preventing heat accumulation, which not only ensures the stability of the display screen operation, but also extends its service life.

d. As an emerging packaging technology, COB technology has high R&D and production costs, especially when the packaging technology is not yet fully mature, , enterprises need to invest a lot of R&D resources and technological transformation in the process of transformation, which directly leads to the price of COB display screens being 10-20% higher than that of LED display screens with the same dot pitch. In addition, the production process of COB display screens is complex and the technical requirements are high, which also increases its cost to a certain extent.

e.COB is mainly for micro-pitch products, and the specifications are mainly P1.53 and below LED display screens, such as P1.53, P1.25, P0.93, P0.78, etc.

Summary

From the above content, we can summarize the difference between GOB LED display screen and COB LED display screena. Different packaging methods

b. Different product specifications

c. Different product prices

The difference between GOB and COB also lies in their launch background. GOB is mainly to solve the waterproof and protective performance problems of traditional LED display screens, while COB is mainly to solve the problems of large dot pitch and low clarity of traditional LED display screens, so the starting points of the two are also different.

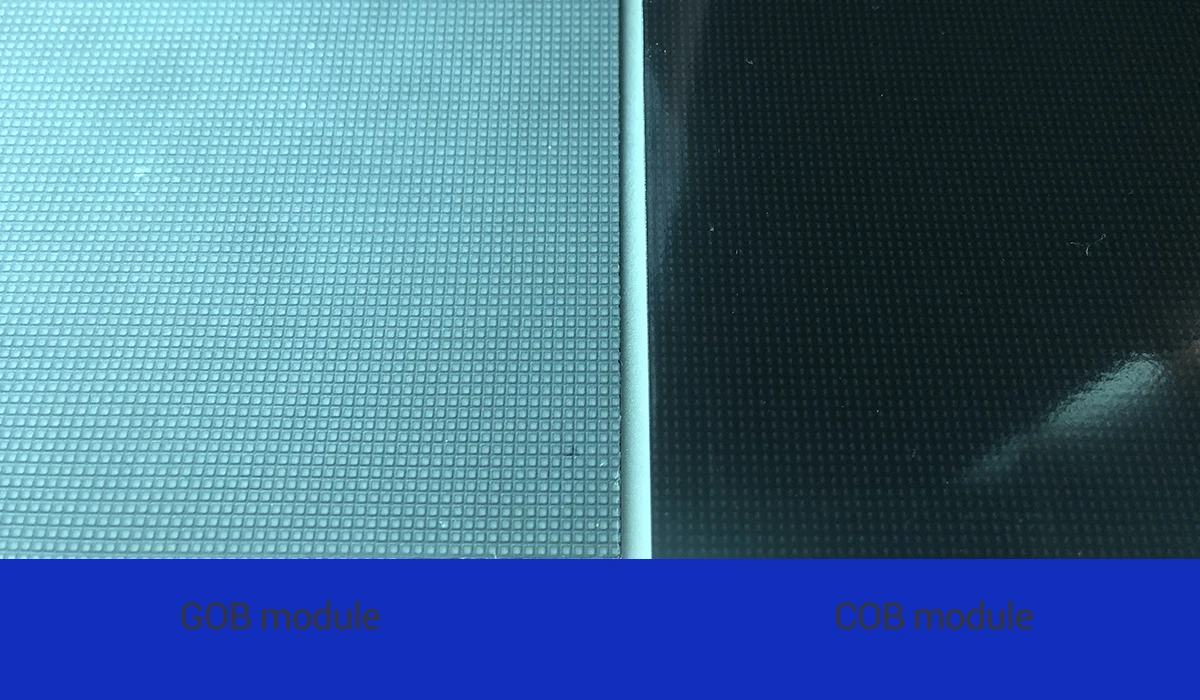

Of course, GOB and COB also have some similarities, that is, good protection and waterproof performance, and secondly, they are mainly used indoors and rarely used outdoors.

In summary, GOB and COB have their own advantages and disadvantages, and the differences are also very obvious. They each occupy a place in the field of display packaging. The main difference lies in the function. GOB is known for protection, while COB meets the needs of the high-end market with ultra-high definition. When users choose LED display screens, they should consider the advantages and disadvantages of the two technologies according to their actual needs and budget and choose the right product.