7 tips for church LED display quality inspection

7 tips for church LED display quality inspection

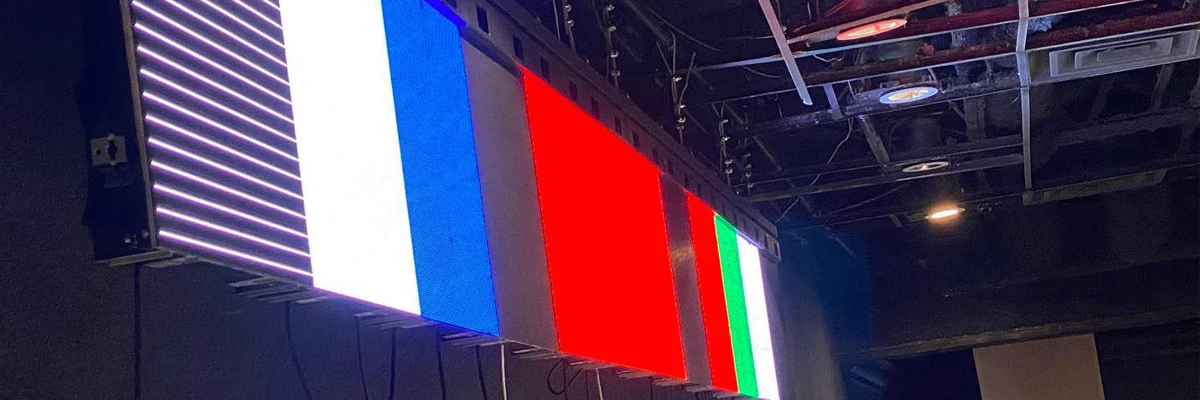

Appearance and Structure Inspection

Upon receiving the display, first check its appearance for any damage, ensure the surface is flat, and verify that no parts are loose or detached.Brightness and Viewing Angle

Use relevant instruments to check the brightness and viewing angle of the display, ensuring the brightness meets standards and checking for uniform brightness across the screen.

Gray Scale and White Balance

Inspect the display's gray scale and white balance levels to ensure they meet requirements, guaranteeing consistent color performance.LED Lights Condition

Carefully check for any dead LED lights on the display. If any issues are found, replacements should be made immediately.Flicker and Stability

Power on the display and check for stability in performance, ensuring there is no flickering.

Waterproofing and Temperature Adaptability

For outdoor displays, check the waterproof rating and operational temperature range to ensure the display can withstand environmental conditions.Electrical Performance Check

Test the display’s energy consumption, voltage, and battery performance to ensure stable operation.

In summary, quality inspection of church displays is a thorough and detailed process. CHIFELED ensures that every display we produce is of the highest quality.

Here is the CHIFELED QC form for you reference:

| LED display quality inspetcion | |||||

| Number | QC item | Standard | Result | Operator | Remark |

| 1 | Purchase order | Quantity,size,accessories match the order requirement | |||

| 2 | LED display surfure | No damage, no stains, no scratches | |||

| 3 | Brightness | Meet product specification requirements | |||

| 4 | Color consistency | No color difference on the surface of the LED screen | |||

| 5 | LED display modules | The gap between led modules should less than 3% of the pixel pitch and the unevenness between led modules should less than 1mm |

|||

| 6 | lamp,mask and case should be assembled consistently without loose or break, the lamps can't be iregular and out of rorder (incline angle should be consistent), no glue on the surface of alamps. |

||||

| 7 | LED display cabinet | There shouldn't be sundries in the cabinet, such as screws, thrums,iron(aluminum) bits, etc. | |||

| 8 | The power and signal cables in LED cabinet should be set up trimly,enlaced beautifully,connected well and tightly.(if the screen will blink when touch the cable) | ||||

| 9 | The instalation position of all cards should be reasonable and tight. | ||||

| 10 | Others | The marks output of the power and signal on the cabinet should be clear and correct. | |||

| 11 | The customer LOGO Printing is clear and the information is correct | ||||

| 12 | The locks installed soundly ,and the door can be easily opened | ||||

| 13 | No loosen screw or misssing (No worm-out screw) | ||||