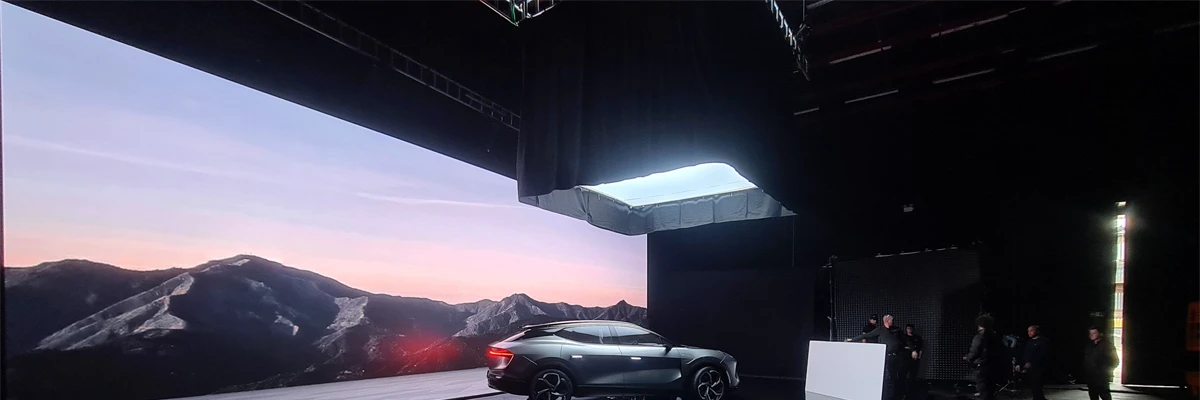

Our COB (Chip on Board) LED display screen represents the latest in LED display technology. It utilizes COB flip-chip technology, where LED chips are precisely bonded directly onto the LED module board.This method employs constant-current drive to protect the LED surface of components, simplifying production processes and minimizing scratches the LED surface.These advancements significantly enhance product stability, reliability, and overall display quality.the COB LED display is the top choice for indoor command control room LED displays, conference LED displays, and educational training LED displays,etc.

High definition & Reliability

COB packaging technology reduces the LED pixel pitch,and improves display screen resolution, providing a clear visual and auditory experience even at close range. At the same time, COB technique directly mounts LED on PCB boards, minimizing collisions and scratches LED surface,improving LED reliability

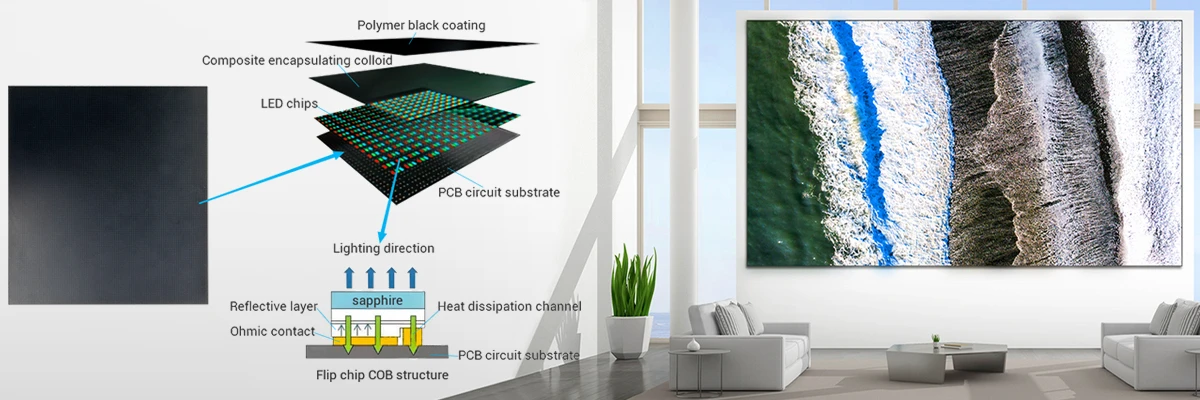

High brightness & Accuracy

Flip-chip (FC) COB refers to LED chips mounted upside down on a PCB with electrical contacts facing downwards. It eliminates the wiring process found in Lateral-chip(LC) COB and further reduces steps in SMD packaging, such as converting LED chips into lamp beads and reflow soldering. This simplifies the production flow and enhances LED accuracy.Additionally, Flip-chip COB technology makes the PCB reflective layer directs light emitted from the LED chips toward the front of the display, resulting in high brightness.

High Speed & Viewing angle

The flip-chip COB can achieve a wide viewing angle of 160°horizontally and 160°vertically, ensuring color, brightness,and frame uniformity from any angle. With the new mass transfer technology, it can transmit 4K Ultra HD signals at high speed.

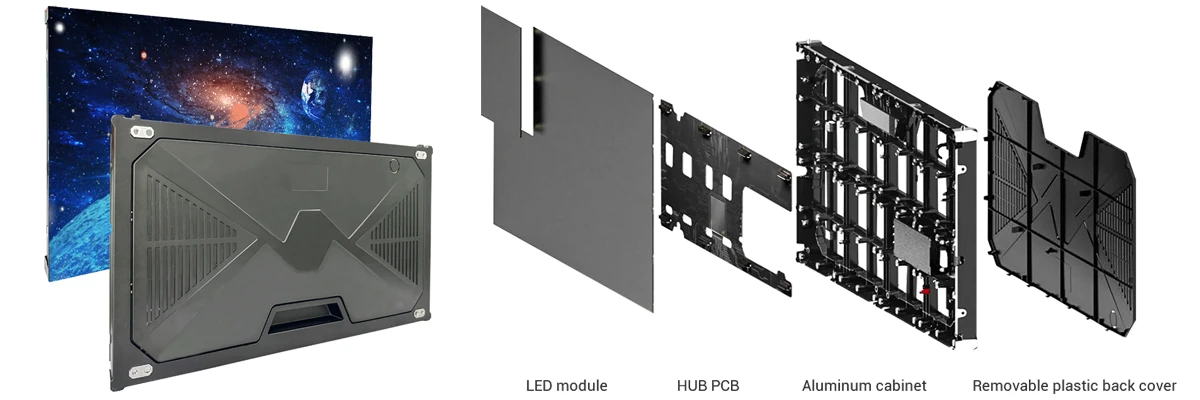

High efficient front maintenance

The LED modules are installed on the front side of the LED display screen using magnets, making installation and maintenance easy and efficient. This design ensures uniform installation across any setting with seamless

splicing technology, eliminating gaps between frames or cabinets.

Front maintenance

The LED display modules are installed on the cabinet using magnets, eliminating the need for screws and wires. It's a plug-and-play setup, saving installation space and providing easy access for maintenance

16:9 golden ratio for HD display.

The cabinet size is 600x337.5mm, designed with a 16:9 golden HD display ratio. Its thickness is only 30mm, making it easy to transport and install.

| Specification | |||

| Pixel pitch(mm) | P0.78125 | P0.9375 | P1.25 |

| Pixel configuration | Flip-chip COB | ||

| Pixel composition | 1R1G1B | ||

| Density (Pixels/m2) | 1638400 | 113000 | 640000 |

| Module size(mm) | 150x168.75 | 150x168.75 | 150x168.75 |

| Module resolution (Pixel) | 192x216 | 160x180 | 120x135 |

| Driving way | Constant current IC | ||

| Driving mode (Duty) | 1/60 | 1/45 | 1/54 |

| Cabinet size(mm) | 600x337.5 | ||

| Brightness(nits) | 600(300-1000 adjustable) | ||

| Refresh rate (Hz) | 3840Hz | 3840Hz | 3840Hz |

| Viewing angle | 150°±75°(H/V) | ||

| Max. power | 350W/m2 | ||

| Ave. power | 120W/m2 | ||

| Input voltage | AC110-240V | ||

| Gamma | 2.8 | ||

| Ink consistency(ΔE*ab) | <1.5 | <0.5 | <0.5 |

| Color temperature(K) | 6500(3000-10000K adjustable) | ||

| Gamut(DCI_P3) | ≥110% | ≥97% | ≥95% |

| Contrast ratio | >100000:1 | >100000:1 | >100000:1 |

| Chroma uniformity | <0.003Δuv | ||

| Chromaticity correction | Incremental luminance chromaticity correction | ||

| Brightness uniformity | >97% | ||

| Color deviation | <3.0 JNCD@30°(U/D/L/R) <5.0 JNCD@60°0(U/D/L/R) | ||

| Color coordinate | Wx:0.31±0.01 Wy:0.32±0.01 | ||

| Operating temperature | -10℃ to +40℃ | ||

| Storage temperature | -20℃ to +60℃ | ||

| Protection Grade | IP54(front side) | ||

| Service | Front maintenance | ||